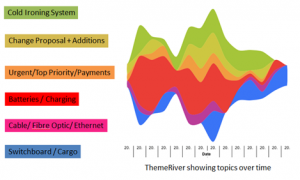

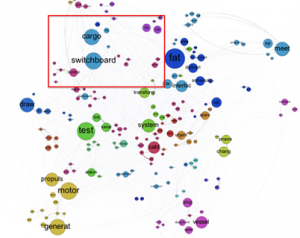

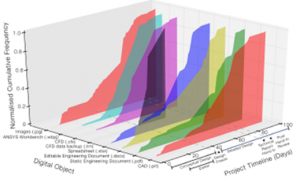

Following the Project Advisory Group meeting of our industrial partners in the summer, and further feedback from industrial partners, the focus of research has been on the following areas: the configuration of prototype project dashboards and the development of the concept of engineering project health monitoring, and in particular, the proxies of performance of engineering projects – i.e. features of interest for project stakeholders. To address the latter a series of ethnographic studies are to be undertaken.

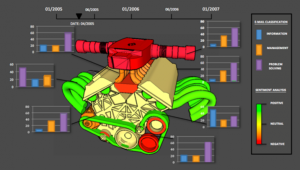

Below are some examples of composites of various analyses we are now able to undertake. Here we are mapping sentiment and type of email being sent onto a representation of a product – who is saying what about each part of the product? This could give project managers valuable early warning about potential issues:

Similarly, this example dashboard shows various information about aircraft repairs, using a visual representation of the aircraft and damage location: